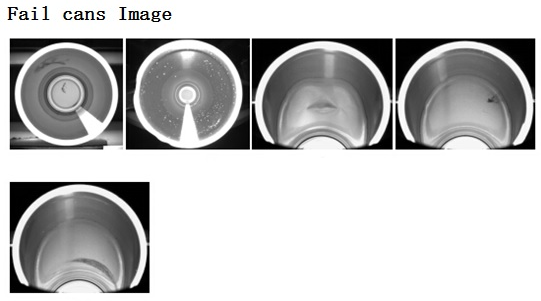

Equipment can be used on product line for detecting the fail cans with mosquito, oil, powder, black spots, bruised, scratched and etc. Accurate detection and rejection fail cans on-line.

It can be customized according to customer's requirements for different kinds of cans, different accuracy requirements.

Technical description

Using proprietary patent technology - strabismus, using 4 high precision BASLER cameras detect the inner-wall of cans, all the interface have no compression,ensure high accuracy for all kinds of cans,especially for the cans with reinforced rib; In addition to using two cameras respectively to detect the top and the bottom of cans. Six cameras complete the highest accuracy detection for cans.

Detection capacity:800 cans per minute

Equipment power:2000W

Equipment voltage:380V

Theoretical precision:0.1 mm/pixel

Equipment advantages

The equipment can work all-weather and 24 hours per day, it can adapt to a variety of cans type on one production line,switch type very simple and rapid.

Easy to operate software, stable and reliable conveyer line, beautiful appearance, to improve product quality, to reduce labor costs.